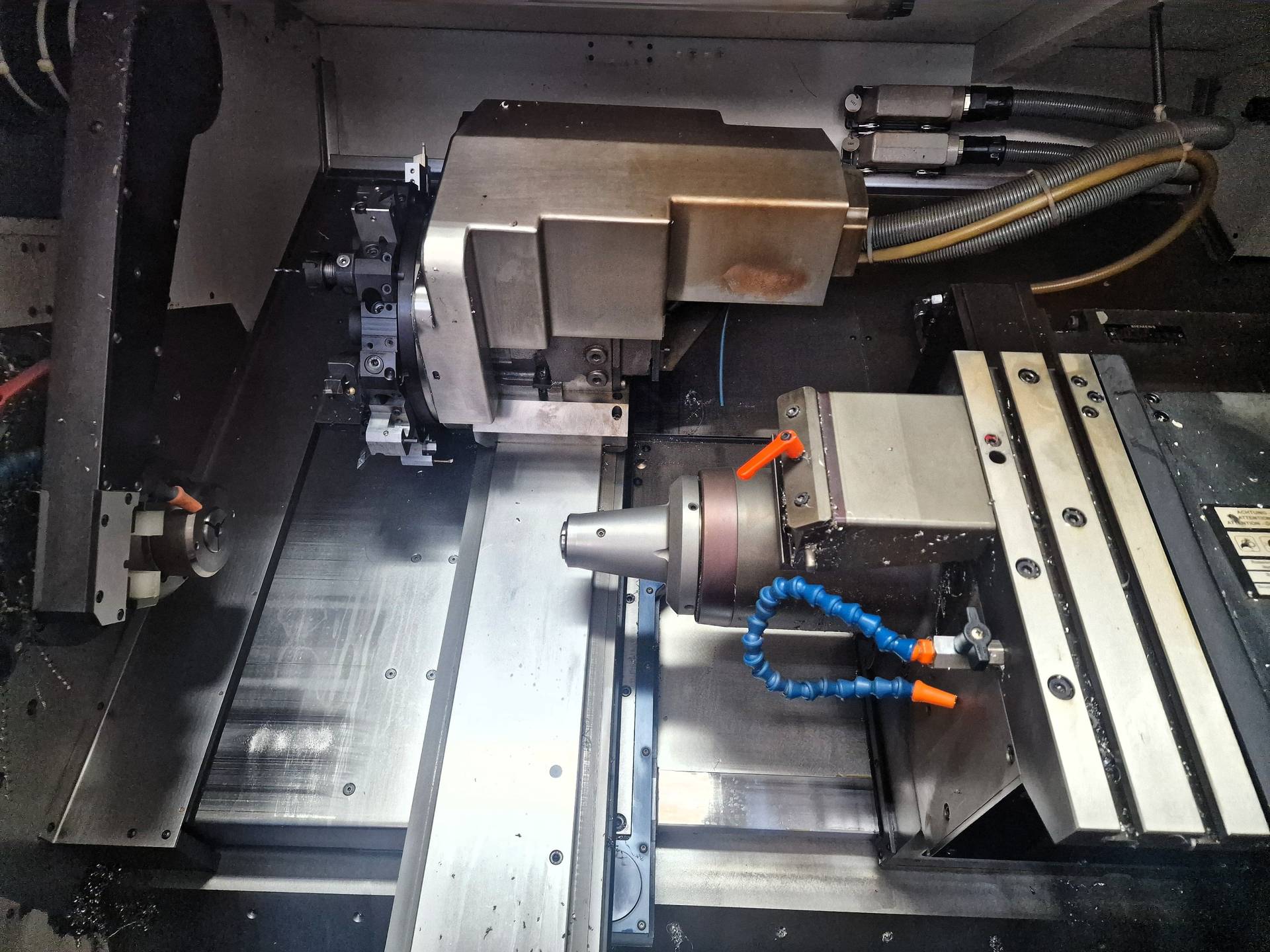

CNC ultra-precision turning with counter spindle

Our CNC ultra-precision lathe sets new standards in high-precision machining. Thanks to state-of-the-art control technology and an integrated counter spindle, it enables the complete machining of complex components in just one clamping operation. The result: You receive JanoTech products with the usual high dimensional and shape accuracy as well as excellent surface qualities that you can rely on.

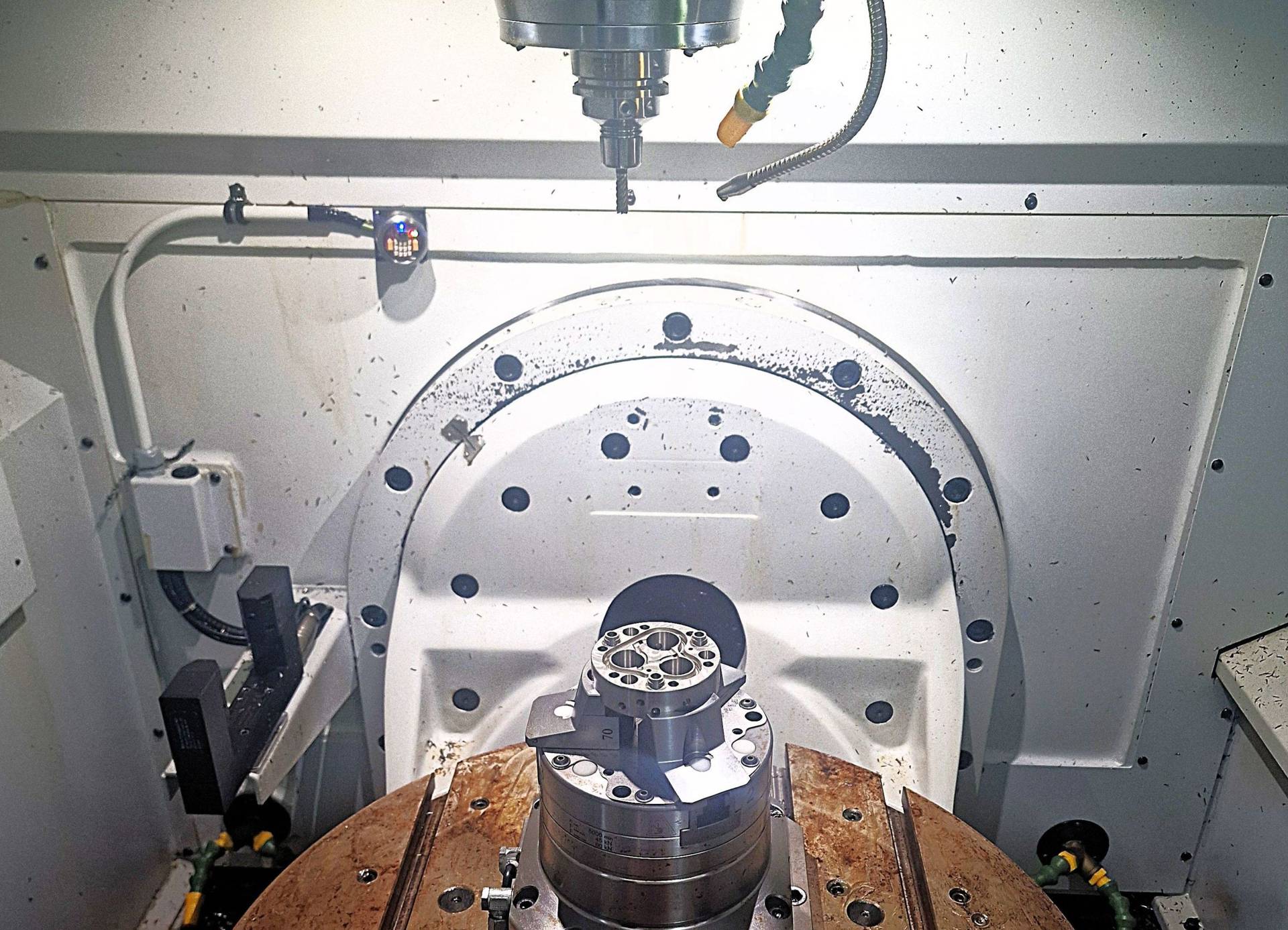

CNC ultra-precision milling in 5 axes

With our 5-axis ultra-precision machining center, we offer you the perfect solution for highly complex components with maximum accuracy. Thanks to state-of-the-art machine concepts and integrated glass scales, we achieve exact position detection, which is the basis for absolute dimensional accuracy and excellent surface qualities. In addition, simultaneous 5-axis machining enables even the most demanding geometries to be produced in just one clamping operation, ensuring maximum precision and repeat accuracy.

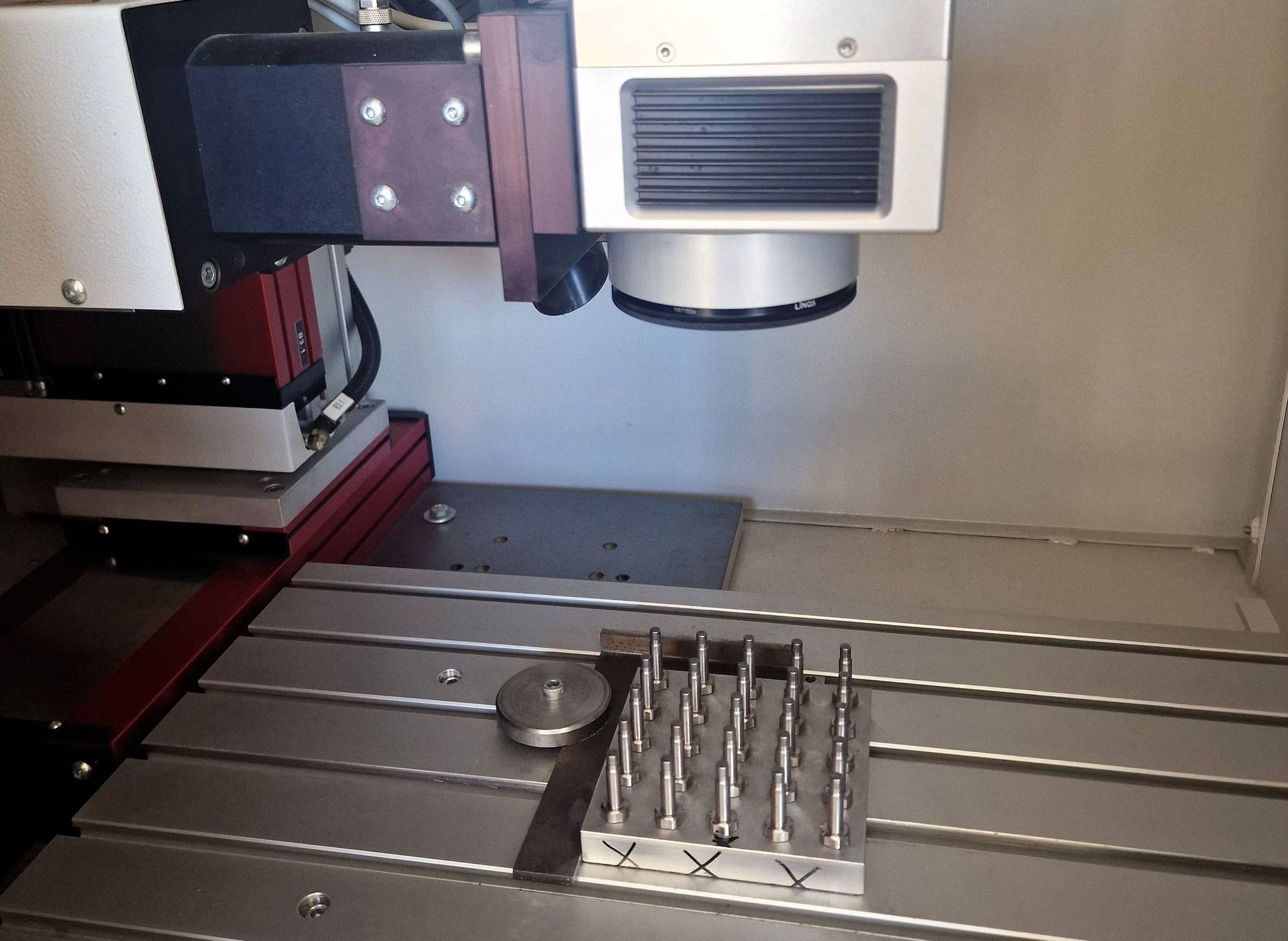

Fiber laser marking & engraving

We use our state-of-the-art fiber laser to produce precise and durable lettering and engravings on a wide variety of materials. Whether annealing markings, fine engravings or the complex production of 3D reliefs - we guarantee maximum accuracy, razor-sharp contours and outstanding legibility. Laser-based marking is wear-free, forgery-proof and ideal for applications where quality and durability are crucial, such as the application of your company name for recognition.

Stereomicroscopy - precision in detail

To ensure the quality of our production at all times, we use state-of-the-art stereomicroscopy. With this technology, components can be inspected down to the smallest detail - three-dimensionally, in high resolution and absolutely reliably. Even the finest structures, surface features or machining marks can be made visible. This guarantees you maximum precision, tested dimensional accuracy and consistently high product quality.

Surface vibratory finishing

For perfect surfaces, we use state-of-the-art mass finishing technology with vibratory vibrators, among other things. This process enables the deburring, smoothing, polishing and cleaning of components with a wide range of geometries - gently, efficiently and with reproducible results. Thanks to the combination of high-quality abrasive media and precisely adapted compounds, we achieve uniform surface qualities, improve corrosion resistance and extend the service life of your components. Ideal for precision parts in air humidification systems and many other applications.

High-tech & craftsmanship for incomparable quality

Our products are not mass-produced. In addition to state-of-the-art CNC technology, we also rely on tried-and-tested machining processes such as turning, milling and drilling. While the blanks are produced on precision machines, the heart of every high-pressure nozzle is carefully manufactured by hand. This is the only way we can achieve the incomparable quality that sets us apart.

Thanks to this know-how, we also manufacture individual special tool holders for CNC machines. The advantage: even where standard tools reach their limits or hard-to-reach areas are inaccessible, we create tailor-made solutions. This enables us to reliably implement even complex requirements and ensure that your components are manufactured to the highest quality.

Unique technologies - protected by trade secrets

Our products owe their exceptional quality not only to state-of-the-art manufacturing and precise craftsmanship, but also to special processes that we have developed ourselves. Some of these techniques deliberately remain our trade secret - a decisive advantage that sets us apart from our competitors. This is how we achieve quality standards that are unparalleled on the market.

Innovation forge between technology center and watch manufacturer

At our current location in 1230 Vienna, Siebenhirtenstraße 7, we combine state-of-the-art technologies with precise craftsmanship - similar to a watchmaker's workshop. The result is a company that has established itself as a true hotbed of innovation.

Our success and the growing demand prove us right: we expand and build a new site just a few steps away - five times as big as before. This gives us even more space to fulfill your wishes with the highest quality and flexibility.